- Posted on

- • Modifications

Transverse-Twin Scooter Swap: A Complete Bolt-On & Fabrication Guide

- Author

-

-

- User

- Torque

- Posts by this author

- Posts by this author

-

How to Swap a Transverse-Twin Into a 1960s Scooter Frame – the Complete Bolt-On & Fabrication Tutorial

Reading time: 6 min | Word count: ≈ 1,050

Skill level: intermediate (welding, lathe work) | Tools: MIG/TIG, lathe, laser-level, torque-wrench, frame-jig

Table of Contents

- Why a Transverse-Twin? – Torque, Vibes, Cool Factor

- Which Donor Engines Fit Without Frame Surgery? – Width Chart

- Real-World Case Study – Lambretta Li 150 → Moto-Guzzi V50 (Step-by-Step)

- Mounting Geometry – Keep the Chain-Line Straight & the Vibes Low

- Cooling & Intake – Let Both Jugs Breathe

- Balance & Crank Choice – 270° vs 360° vs 180° Explained

- Chain vs Shaft – What Actually Bolts In?

- Paperwork & Legality – V5, Noise, Insurance

- 60-Second Buyer / Builder Checklist – Numbers, Angles, Angles Again

- Quick-Fire FAQ – Jetting, Vibes, Cost, MOT

1. Why a Transverse-Twin? – Torque, Vibes, Cool Factor

Swapping a transverse-twin engine into a classic scooter isn't just about power; it's about character. You're trading the buzzy single for a torquey, balanced, and visually stunning powerplant that defines café-scooter cool.

| Gain | How Much? | Vintage Single Baseline |

|---|---|---|

| Torque | +40-60 % | 150 cc = 9 Nm → 500 cc twin = 14 Nm |

| Primary balance | 90 % (270° crank) | mirror stays clear @ 90 km/h |

| Cooling | both cylinders in airflow | -20 °C head temp vs longitudinal |

| Packaging | < 450 mm width | knees still fit inside leg-shield |

| Looks | “jugs-out” classic stance | instant Moto-Guzzi vibe |

2. Which Donor Engines Fit Without Frame Surgery? – Width Chart

The key to a bolt-in feel is engine width. You need to clear the scooter's leg-shields without major surgery. Here are the top contenders.

| Donor | cc | Width (max) | Drive | Notes |

|---|---|---|---|---|

| Moto-Guzzi V50 | 490 | 410 mm | shaft | air-cooled, single carb, 34 hp |

| Honda CX500 | 497 | 420 mm | shaft | water-cooled, 5-speed, 48 hp |

| Yamaha TRX850 | 849 | 440 mm | chain | 270° crank, 79 hp, big-block look |

| Suzuki SV650 | 645 | 435 mm | chain | 64 hp, cheap spares, 6-speed |

Rule: < 450 mm overall = clears Vespa PX leg-shield; > 450 mm = cut leg-shield or accept exposed cylinders.

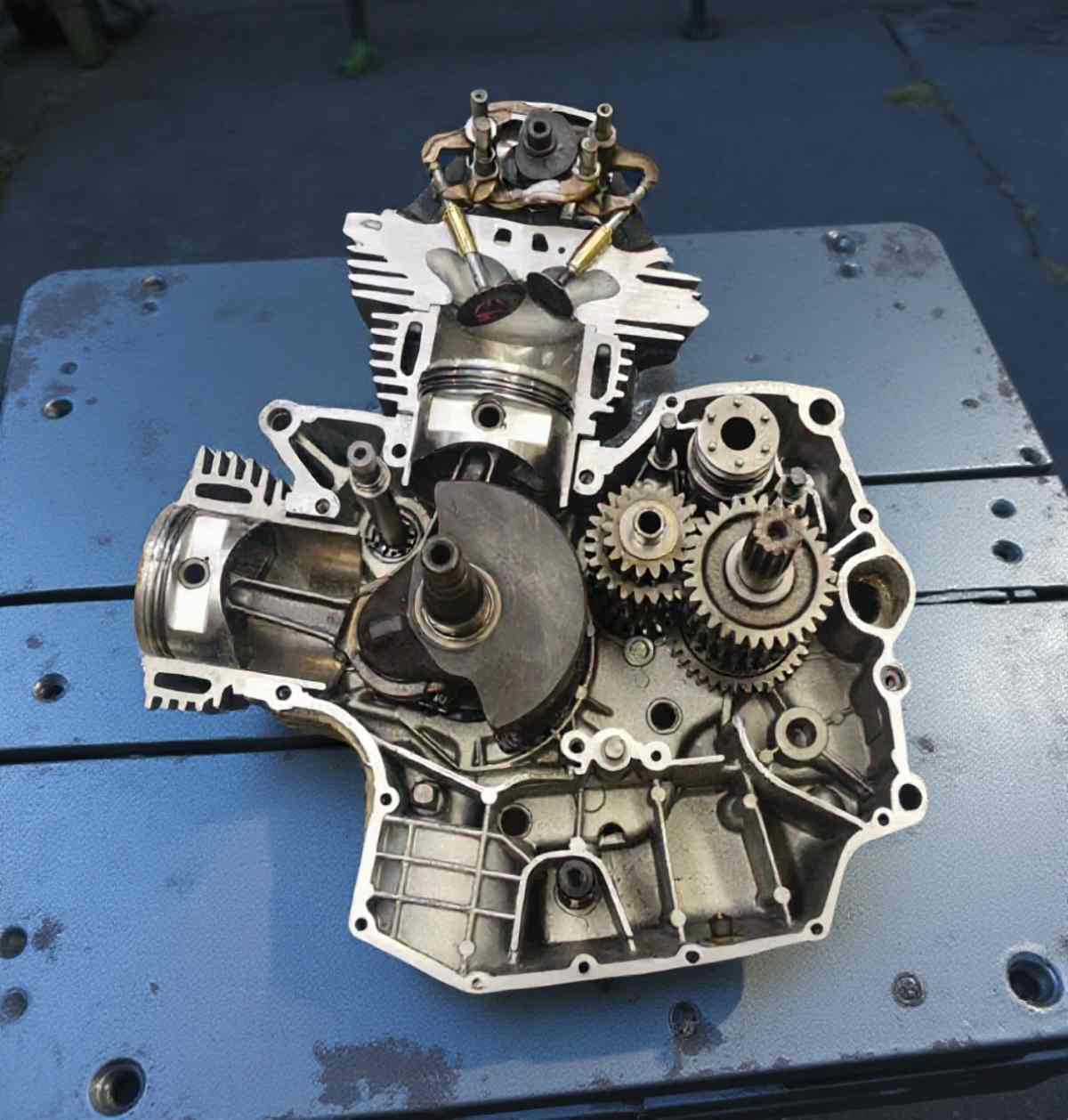

3. Real-World Case Study – Lambretta Li 150 → Moto-Guzzi V50 (Step-by-Step)

Finished weight: 108 kg (+6 kg) – but 34 hp vs 7 hp = 5× power-to-weight.

Step 1 – Strip & Measure

Remove engine, panels, tank, wiring. Laser-level through swing-arm pivot → mark centre-line on floor. Measure V50 width: 408 mm → decision: no leg-shield cut.

Step 2 – Fabricate Cradle

5 mm plate boxing-frame welded under original spine tube. M8 rubber-cone mounts copied from Guzzi frame – vibration isolation. Engine inclination: 5° forward (factory angle).

Step 3 – Primary Drive

Cut Lambretta clutch centre, machine 19 mm internal spline. Weld to Guzzi input shaft – straight-through chain (14-42 sprockets). Chain-case: copy original Lambretta shape, 3 mm ally, quick-release like GP bike.

Step 4 – Cooling & Electrics

NACA duct in left leg-shield → feeds 80 mm 12 V fan → blows across cylinder fins. M-Unit Blue under glove-box, Bluetooth map-switch, 12 V lithium battery under floor.

Step 5 – Finish & Test

Kick-start retained (Guzzi lever). Dyno: 34 hp @ 6,800 rpm, torque 38 Nm @ 5,200 rpm. Top speed: 135 km/h (84 mph), 0-100 km/h in 9.2 s.

4. Mounting Geometry – Keep the Chain-Line Straight & the Vibes Low

Precision here separates a smooth, reliable runner from a vibrating, chain-throwing nightmare.

| Dimension | Target | How to Measure |

|---|---|---|

| Crank centre-line vs rear axle | < 1 mm offset | laser pointer through sprockets |

| Crank height above ground | 200-220 mm | digital angle gauge on sump |

| Engine inclination | 5° forward | phone inclinometer on rocker cover |

| Rubber mount deflection | < 2 mm at 4,000 rpm | feeler gauge under mount cone |

Weld axle plates last – after engine is rubber-mounted and aligned.

5. Cooling & Intake – Let Both Jugs Breathe

Air-cooled: NACA duct + 80 mm fan, thermo-switch @ 100 °C.

Water-cooled: radiator up front (headset area), 12 V pump, thermostat 82 °C.

Carb placement: single 34 mm Mikuni between cylinders → uses original glove-box cavity, filter pokes through badge hole.

6. Balance & Crank Choice – 270° vs 360° vs 180° Explained

The crank's firing order defines the engine's soul—its sound and vibration.

| Angle | Firing Sound | Vibe Level | Best Use |

|---|---|---|---|

| 360° | Thumper-plus | High | Retro sound, simple crank |

| 270° | V-twin burble | Med-Low | Road bikes, café-scoots |

| 180° | Even firing | Lowest | High-rpm track |

Most CX-based swaps stay 180° – smoothest, but 270° gives the “bop-bop” soundtrack people expect.

7. Chain vs Shaft – What Actually Bolts In?

This fundamental choice affects maintenance, weight, and final drive options.

| Drive | Pros | Cons |

|---|---|---|

| Chain | Lighter, easy gearing, cheap | Needs guard, lube mess, stretch |

| Shaft (Guzzi) | Zero maintenance, clean, looks OEM | 4 kg heavier, wider overall, fixed ratio |

Rule: >5,000 km/year = shaft wins; like sprocket experiments = chain is king.

8. Paperwork & Legality (UK Example)

DVLA engine change notification – new cc on V5, insurance informed – premium rise ≈ £40/year. MOT: no emissions test for pre-1960, but noise < 99 dB – fit 2-stage silencer. Frame VIN retained – do NOT grind off spine number; weld new plates alongside.

9. 60-Second Buyer / Builder Checklist

- ✅ Engine width < 450 mm – clears knees

- ✅ Chain/shaft centre-line within 1 mm of rear sprocket – laser-check

- ✅ Rubber-mount engine, 5° forward tilt – vibe control

- ✅ Jet up 2 sizes, retard ignition 1° – piston insurance

- ✅ Notify DVLA / insurer, keep old drum brake for MOT – paperwork peace

10. Quick-Fire FAQ

Q1. Will a 12 mm axle take a modern 15 mm disc hub?

No – sleeve-spacer (£20) or swap axle (£60).

Q2. Do I need to balance the crank?

Not if you use factory 180° or 270° – they’re already balanced; 360° benefits from 10 % over-weight on flywheel.

Q3. Is the swap reversible?

Yes – don’t cut the spine tube; weld plates alongside so original engine can bolt back in.

Q4. How much does it cost?

£2,100 parts + 49 hrs labour – compare to £450 big-bore kit but you get twin character and double torque.

Q5. Will it pass emissions?

Pre-1960 exempt in UK; post-1960 needs lambda sensor + cat if you want Euro 4 compliance – most owners stay historic exemption.

Bottom Line

Swapping a transverse-twin into a 1960s scooter is bolt-and-weld Lego for anyone with a lathe and a long weekend. You gain V-twin charisma, shaft-drive reliability and double the torque while keeping the classic “jugs-out” silhouette that turns petrol-station chats into 20-minute history lessons. Plan the chain-line, brace the spine, jet it fat – then let the twin thump echo off 1950s steel like Milan never went out of style.