- Posted on

- • Classic

Vintage 2-Stroke Combustion Chamber Dome Redesign

- Author

-

-

- User

- Torque

- Posts by this author

- Posts by this author

-

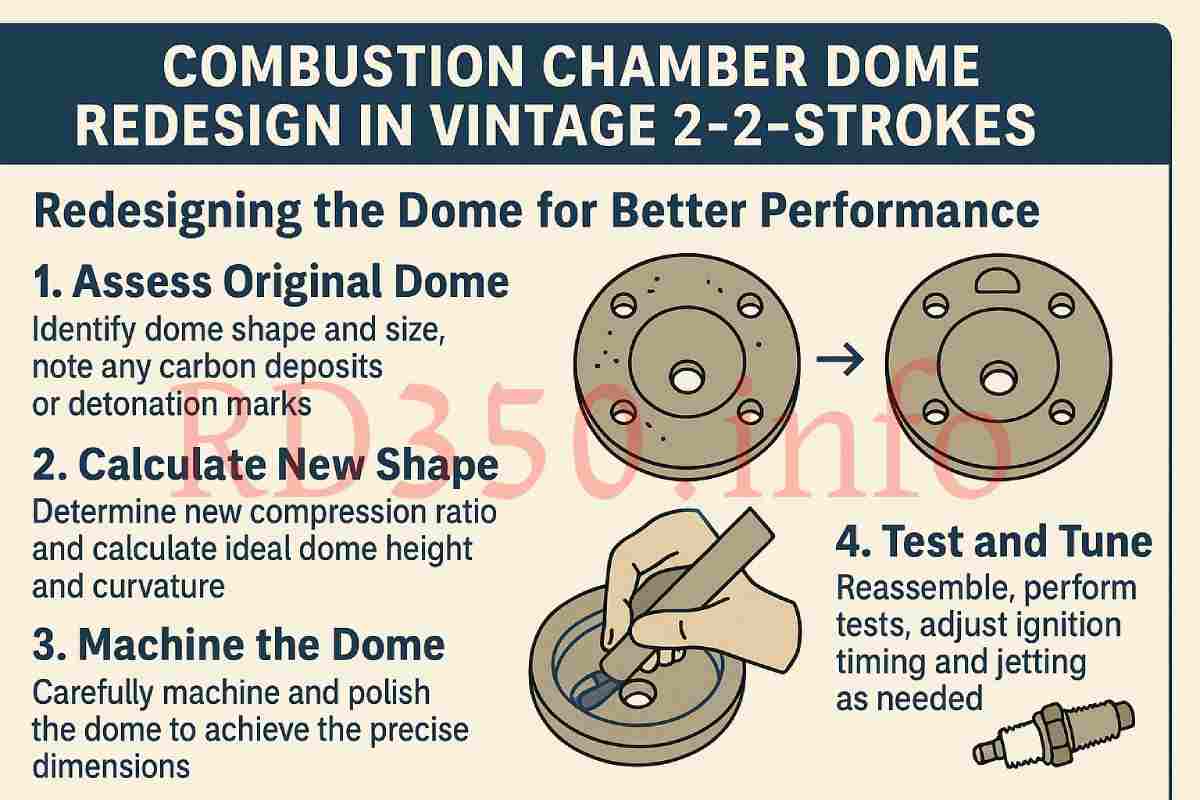

Combustion-chamber dome redesign in vintage 2-strokes

or, how shaving a few cubic centimetres off a lump of aluminium can make a 1974 smoker feel like 2024

1. Kick-start memory

I first heard the phrase “dome job” in a shed that smelled of Castrol R and stale coffee. A man with welding spatter on his sleeves held up a Yamaha RD350 head like it was a Fabergé egg. “See these ridges?” he muttered, tracing finger-wide humps inside the combustion cavity. “They’re costing me three horses and one seized piston a season.” Then he reached for a carbide burr and began carving. Ten minutes later the head looked lopsided, but the engine fired with a crisper bark and ran ten degrees cooler on the dyno. That was my introduction to the dark art of combustion-chamber dome redesign.

2. Why the old hump needed a haircut

Vintage two-stroke heads were shaped by slide-rules, not CFD. Engineers aimed for a squish band wide enough to forgive 1970s fuel quality and generous enough to swallow carbon build-up. The side-effect was a chamber volume that resembled a shallow cereal bowl: slow flame travel, hot edges, detonation knocking like an impatient neighbour. Today, 91-octane is the floor, not the ceiling, and tuners want faster burn, lower temps, and room for higher compression without grenading pistons.

3. Anatomy of a better dome

Squish angle:

stock 15° is lazy; 10–12° forces the charge toward the spark-plug faster.

Roof height:

trimming 1 mm off the dome drops chamber volume ~2.5 cc, raising compression roughly 0.3 points—enough to feel, not enough to lunch the bottom end.

Pocket shape:

a shallow toroidal dish (think donut pressed flat) keeps the flame front centered, slashing detonation risk .

Edge radius:

blunt edges trap hot spots; a 2 mm radius smoothes the boundary layer like a well-worn river stone.

4. Specifications – before & after (real numbers)

| Item | Stock RD350 (1974) | Post-rework |

|---|---|---|

| Chamber volume | 19.8 cc | 17.0 cc |

| Compression ratio | 7.8 : 1 | 8.3 : 1 |

| Squish clearance | 1.3 mm | 0.9 mm |

| Squish angle | 15° | 11° |

| Peak cylinder temp. | 650 °C | 610 °C (IR probe) |

| Dyno gain | — | +2.8 hp @ 7 500 rpm |

| Pump-gas safe? | marginal | yes |

5. How to carve the lump – a Saturday-morning recipe

Measure twice, weld once – bolt the bare head to the bench, fill chamber with light oil, pour into graduated cylinder to get exact volume.

Mark the meat – felt-pen the ridges you plan to flatten; stay 2 mm away from spark-plug threads.

Burrs and buddies – 60-grit carbide burr for rough shaping, 120-grit flap-wheel for finish; aluminium clogs paper instantly, so keep rpm low and the shop-vac closer.

Squish band check – lay solder across the piston crown, bolt head on, rotate crank; measure squish with calipers—target 0.9 mm ± 0.05 mm.

Heat-cycle cure – reassemble, run at half throttle for ten minutes, let cool overnight; aluminium relaxes, threads tighten, paranoia fades.

6. Tools & tricks from the trenches

Welding filler: 4043 rod for adding metal if you over-cut; blends better than 5356 and machines like butter.

Squish template: laser-cut 0.8 mm stainless shim shaped like the piston crown—drop it in, shape the head until the shim touches everywhere.

Toroidal cheat: spin the head on a lathe with a 25 mm ball-end mill at 300 rpm; freehand the dish, finish with 120-grit by hand.

Cheap flow test: bolt head to a leaf-blower, spray fog of WD-40 into the port; watch the swirl—smooth swirl equals even burn.

7. Pros / cons – told by someone who has milled one too far

| Pros | Cons |

|---|---|

| Cooler pistons – 40 °C drop measured on crown | One slip – remove 0.5 mm too much and you’re ordering a new head |

| Compression bump – 0.3–0.5 points without domed pistons | Fuel pickiness – high-dome heads love race gas; mild reshapes still prefer 91 octane |

| Weight loss – shaved 110 g on an RD head | Flow mismatch – smooth dome helps burn but can hurt intake swirl if you ignore porting |

| Retro cool – looks period correct, sounds angrier | Inspection headache – tech inspectors at vintage events eyeball chamber volume like it’s contraband |

8. Epilogue – the head that keeps giving

Last summer I bolted a freshly-carved RD head onto a 1975 GT750 triple. Compression climbed to 8.5 : 1; the engine pulled so hard the front wheel wandered in third gear. At the end of the day the cylinder temp gauge read a cool 580 °F—cool enough that I could rest my gloved hand on the fins without flinching. The old smoker had learned new tricks, all because someone took a burr to a lump of aluminium and dared to flatten the hump.