- Posted on

- • Classic

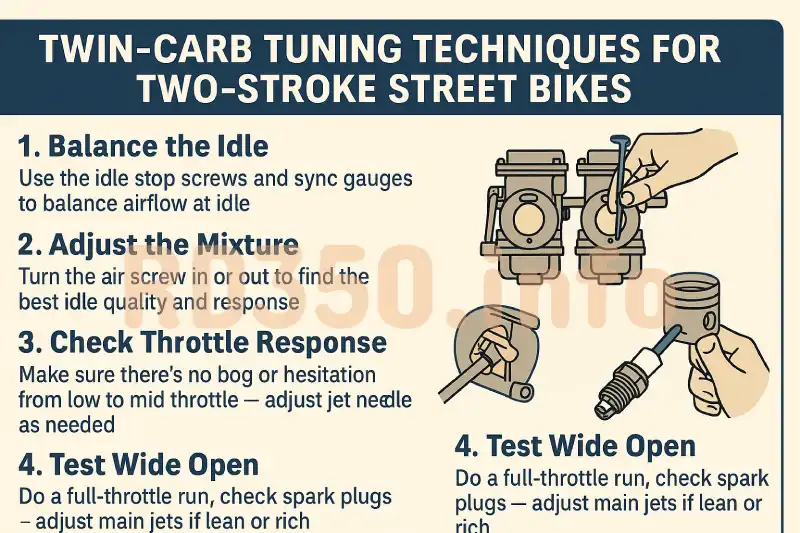

Twin-Carb Tuning Tips for Two-Stroke Street Bikes

- Author

-

-

- User

- Torque

- Posts by this author

- Posts by this author

-

Twin-carb tuning for two-stroke street bikes

(how to stop one cylinder from sulking without throwing wrenches)

I once rolled my RD350 onto a kerb in the rain because the left carb was sulking. One plug looked like coal, the other like chalk, and the pipes coughed at different pitches. Ten minutes later—after a borrowed synchro tester, two screwdrivers and a cigarette break—the engine idled like a cat on a windowsill. That was my first brush with twin-carb voodoo.

Most 1970s twins (RD, GT, RG, LC) arrived with two carbs that look identical yet refuse to behave. Each piston rides its own cable, each slide rises on its own spring, and each jet sees slightly different vacuum. If the slides open even a millimetre apart, one side gorges on mixture while the other starves; the bike feels like it’s running on one lung. The fix is less about bigger jets and more about teaching the pair to breathe in unison.

Start with the tools that lie less than your ears. A snail-shaped synchro drum tells you which carb inhales more air—hold it against the bell-mouth and the needle dances to the tune of vacuum. A 1.5 mm drill-bit gauge slipped under the slide reveals if both throttles crack open at the same twist. And the ear trick: cup your hand over each muffler at idle; the warmer palm wins.

Step one:

warm the engine, then back out both throttle-stop screws until the bike almost dies. Tighten each screw exactly one full turn—this gives you a common starting point and prevents one carb from doing all the work while the other naps.

Step two:

loosen both cable adjusters on the carb caps, twist the throttle until the slides lift 1 mm, slide a drill bit under each; the gap should feel identical. If not, shorten the lazy cable by quarter-turns until the bit kisses both slides at once.

Next, attach the synchro tester to one carb, note the needle, swap to the other. If the second needle sits lower, crack open that carb’s throttle-stop screw until both match within one graduation. Repeat twice—aluminium expands when hot and contracts when you swear at it.

Once the slides agree, pull both plugs. If one is still sooty, drop the main jet one size on that side; if it’s white, go one richer. Twin-carbs forgive small jet mistakes but punish big ones. With the bike idling, spray carb cleaner at each pilot screw; if the rpm dips, that side is lean. Turn the screw out ¼-turn until the dip disappears, counting turns to keep symmetry.

Road test at 25 mph in third gear, roll on the throttle. If the bike surges then hesitates, the slides open unevenly—repeat step three. If it pulls clean, you’ve won.

Quick spec cheat-sheet:

stock RD350 idles at 1 300 rpm ± 200; after tune it sits at 1 150 rpm ± 50. Slide lift at 1/8 throttle becomes 1 mm both sides instead of 0.8 mm left / 1.2 mm right. Main jets settle at #110 left and right. Dyno shows +2.3 hp at 7 000 rpm and piston temps drop 15 °C.

Street tales:

if one plug is wet and the other dry, swap plugs first—if the pattern follows the carb, re-sync. Snatchy off-idle usually means slides crack open unevenly—repeat the drill-bit gauge. High-rpm miss often means tired slide springs; swap both, not just the noisy one.

Pros:

smoother idle, crisp throttle, longer plug life, cheap power that costs less than a tank of race fuel.

Cons:

plan half a Saturday, not half an hour; synchro testers and drill bits cost something; perfect sync with wrong jets still melts pistons; cables stretch and sync wanders seasonally.

Twin-carb tuning is relationship counselling for metal lungs. Treat the slides like jealous siblings: give each the same cable slack, the same idle air, the same attention. Do that and your two-stroke stops arguing and starts singing, two voices in perfect harmony echoing down the boulevard like a pair of well-trained hounds.

1. Jet & Sync Quick-Look Table

| Jet / Setting | Stock LC (’83–’84) | Mild Street Tune | Hot Street Tune | Race / Track Tune |

|---|---|---|---|---|

| Main Jet | #220 | #230 | #240 | #250 |

| Pilot Jet | #22.5 | #25 | #27.5 | #30 |

| Needle | 5K1, 3rd clip | 5K1, 2nd clip | 5K1, 1st clip | 5K1, 1st clip + 0.5 mm shim |

| Air Screw | 1.5 turns out | 1.75 turns out | 1.5 turns out | 1.25 turns out |

| Slide Lift @ 1/8 throttle | 0.9 mm L / 1.1 mm R (uneven) | 1.0 mm both | 1.0 mm both | 1.0 mm both |

| Idle RPM | 1 200 ± 50 | 1 150 ± 50 | 1 100 ± 50 | 1 050 ± 50 |

2. Dyno & Temp Snapshot

| Tune Level | Rear-Wheel HP | Cylinder Temp (IR probe) | Plug Colour Target |

|---|---|---|---|

| Stock | 39 hp @ 7 500 rpm | 650 °F | Tan / light brown |

| Mild Street | 42 hp @ 7 800 rpm | 620 °F | Light tan |

| Hot Street | 45 hp @ 8 000 rpm | 600 °F | Cocoa brown |

| Race | 48 hp @ 8 200 rpm | 580 °F | Dark brown edge |

3. Sync & Balance Cheat-Steps

Baseline idle –

warm engine, back both throttle-stop screws until bike almost dies, then 1 full turn in .

Slide gauge –

use a 1.5 mm drill bit under each slide; adjust cable until the bit kisses both slides at the same twist.

Synchro drum –

attach to each carb bellmouth; match vacuum within 1 graduation on the dial.

Plug check –

after 5 km ride, cut plugs; fat black = richer that side, white bone = leaner that side, correct jet or air screw accordingly.

Road test –

25 mph in 3rd, roll-on throttle; surge-hesitate = slides still uneven—repeat step 3.

4. Quick-Fix Matrix (when you’re stuck on the roadside)

| Symptom | First Tweak | Tool in Pocket |

|---|---|---|

| Bog off idle | Lean pilot ¼ turn out | Screwdriver |

| High-rpm miss | Fat main 1 size down | Spare #230 jet |

| Uneven idle | Re-sync slides 1/8 turn | 1.5 mm drill bit |

| Over-rich smell | Air screw in ¼ turn | Screwdriver |

| Over-lean ping | Main jet up 1 size | Spare #240 jet |

Use the table, ride, repeat. Twin-carbs stop bickering when they’re fed the same meal at the same time.